Although it was only recently used in the architectural, engineering, and construction (AEC) sector, laser scanning is not a new technology. The precision of 3D laser scanning of structures in the construction sector, according to industry research, has raised demand for the technology by 57%, and the market is predicted to rise by 10 billion USD by 2024

I. What Is Laser Scanning in the Construction Industry?

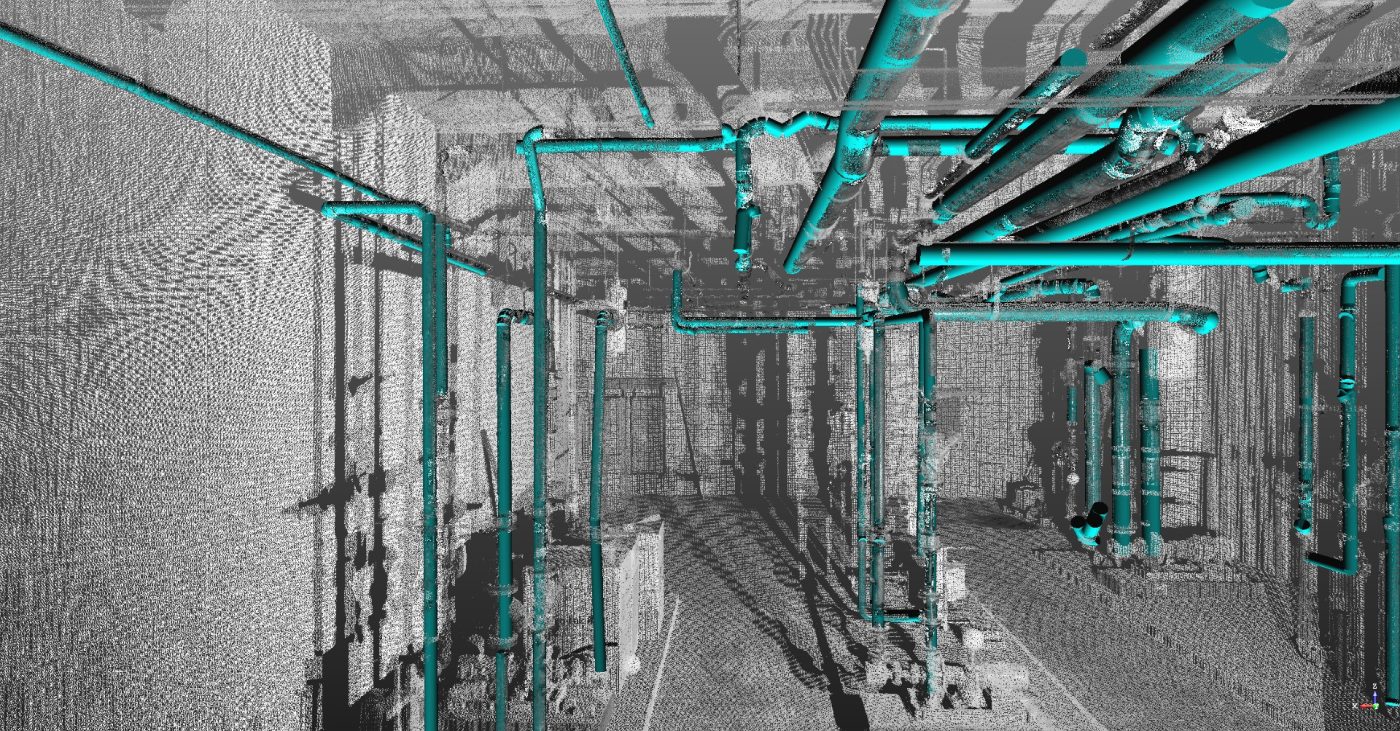

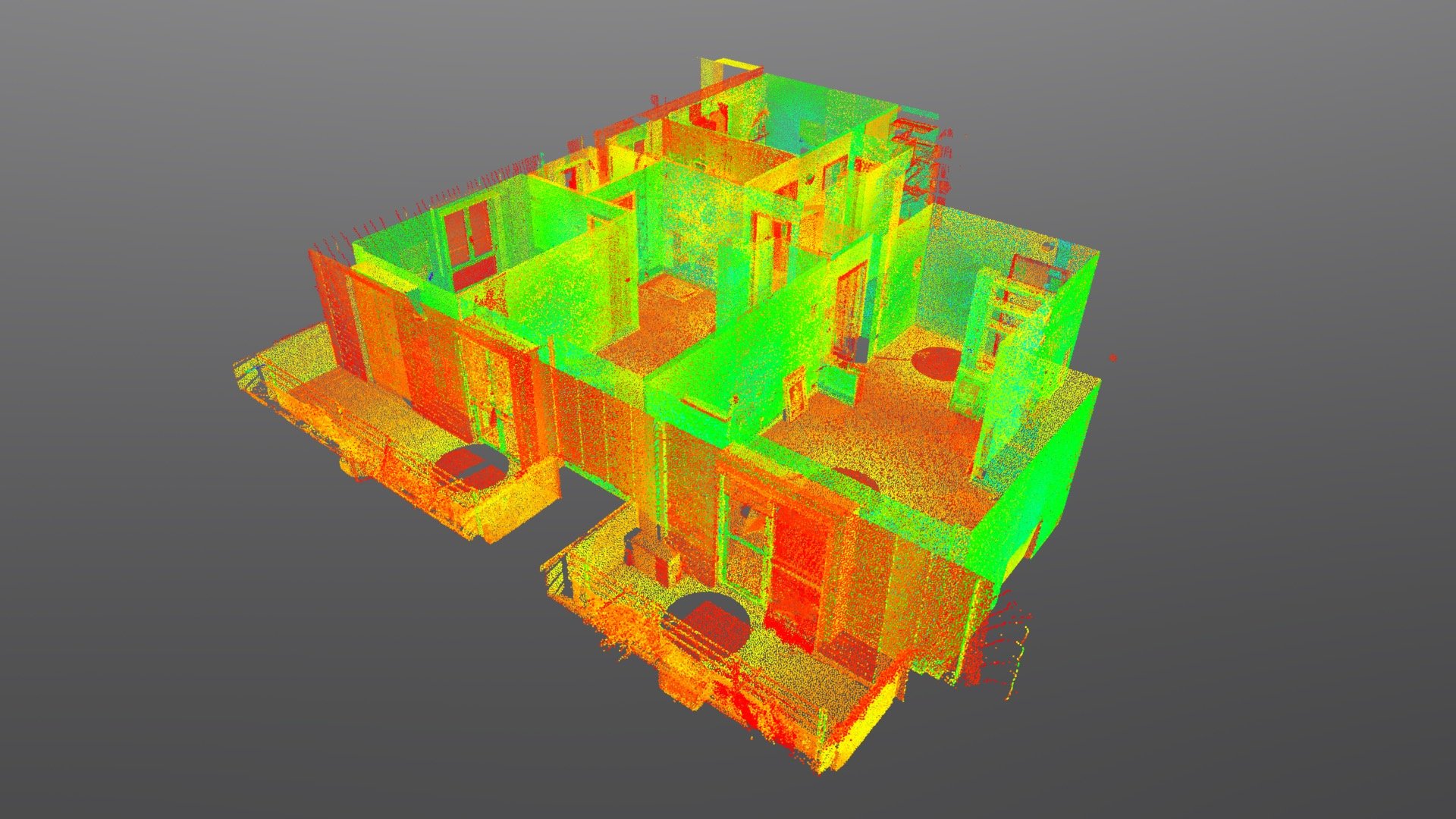

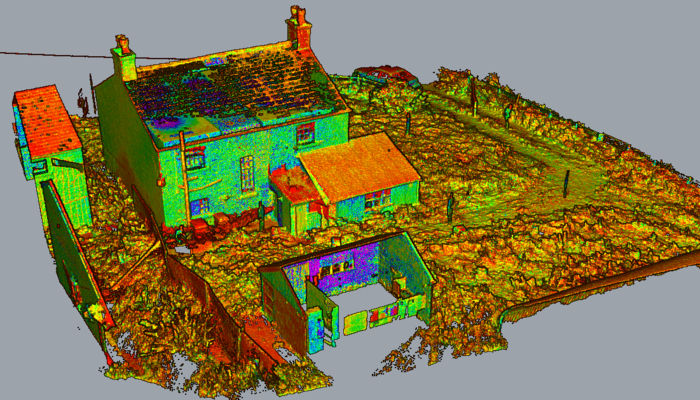

3D Laser scanning technology, in the construction industry, is a method for precise documentation of physical objects and spaces using LiDAR (Light Detection and Ranging). It operates by emitting laser pulses to measure the time taken for the laser beam to bounce back from surfaces in the scanned environment.

This process generates extensive coordinates, including X, Y, and Z values, forming a point cloud representation of the scanned area. 3D laser scanning offers rapid, efficient, and highly accurate data capture for structures and objects in real-time. This technology has become indispensable in the construction industry, facilitating tasks like as-built documentation, quality control, clash detection, and site analysis. It’s particularly valuable for capturing data from inaccessible, large-scale, or deteriorating buildings.

II. Top 6 Benefits of 3D Laser Scanning in the AEC Industry

- Time Efficiency 3D laser scanning drastically expedites data collection compared to traditional surveying methods. Laser scanners can capture millions of data points within minutes, providing a comprehensive site or structure scan. This speed enhances the efficiency of acquiring accurate as-built information, saving time in the initial project stages and accelerating decision-making processes.

- Precision in Measurements One of the most notable advantages of 3D laser scanning in the construction industry is its unparalleled surveying accuracy. These scanners deliver precise measurements, resulting in detailed point cloud data. This data can be transformed into reliable 3D models, forming a strong foundation for design, construction, and analysis. Such precision significantly reduces errors and enhances project deliverable quality.

- Comprehensive Documentation 3D laser scanning provides detailed documentation of existing sites or structures, capturing intricate details and dimensions. The generated point cloud data and 3D models serve as digital records, aiding design modifications, facility management, and ongoing maintenance. This comprehensive documentation streamlines decision-making processes, ensuring seamless alignment with existing conditions in future expansion work.

- Cost-Efficiency Accurate as-built data obtained through laser scanning minimizes errors, clashes, and rework during design and construction phases. This is a key benefit, as it fosters better collaboration among stakeholders, reducing the chances of costly alterations. Early identification and resolution of potential issues lead to more efficient project timelines and budget management.

- Enhanced Site Safety 3D laser scanners can remotely capture structural data, reducing the need for manual measurements in potentially hazardous areas. This minimizes risks associated with working at heights, unstable structures, or confined spaces. Improved safety measures create a healthier work environment and reduce on-site accidents.

- Minimized Downtime In industries where shutdowns or facility downtime are costly and disruptive, 3D laser scanning plays a vital role in minimizing these interruptions. Quick and accurate capture of as-built conditions enables precise planning and execution of retrofits, renovations, or upgrades with minimal disruption. Detailed measurements and information from scanning allow for efficient prefabrication and installation, reducing overall downtime.

III. Applications of 3D Laser Scanning in the AEC Industry

3D laser scanning has a wide range of applications in the Architecture, Engineering, and Construction (AEC) industry:

- As-Built Documentation Drawings

- Construction Planning and Management

- Architectural Documentation and Historical Preservation

- Virtual Design and Construction (VDC)

- Facility Coordination

- Collecting Geospatial Data

- Creating Digital Twin Solutions

IV. Essential 3D Laser Scanning Equipment for the AEC Industry

Key equipment required for a 3D laser scanning project in the AEC industry includes:

- 3D Laser Scanner

- Tripod or Mounting System

- Targets or Reference Points

- Laptop or Tablet

- Batteries and Chargers

- Data Storage

- Specialized Software

As technology continues to evolve, 3D laser scanning is becoming more portable and accessible for on-site and remote applications. Integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms with 3D laser scanners is expected to automate data interpretation, enabling faster and more accurate analysis of complex datasets. This paves the way for innovative design and construction practices in the industry.

For more information on 3D laser scanning processes, please contact:

- Hotline: +855 88 520 30 40 / +855 97 9999 658

- Email: admin@onebim.asia

- Website: https://onebim.asia

Khmer (Cambodia)

Khmer (Cambodia)